Employees of IPMash RAS discovered a way to reduce the vibration frequencies of liquids in containers

Employees of the Laboratory of Mathematical Modeling of Wave Processes of the Institute of Problems of Mechanical Engineering of the Russian Academy of Sciences (IPMash RAS) have found out how to reduce the frequency of liquid vibrations in cylindrical vessels used for the transportation of liquid cargo, such as liquefied natural gas; such fluctuations create an additional load on the walls, that can produce negative consequences. It turns out, that, to reduce the frequency of vibrations, it is enough to place a vertical radial partition to the full depth of the liquid. The results of the study are published in the journal Physics of Fluids.

The problem of studying fluid fluctuations in vessels has arisen long ago and remains currently topical in connection with the sea transportation of liquid cargo (in particular, liquefied natural gas). In the 50-ies of the last century, its study was initiated in connection with the development of rocket technology — fluctuations of liquid fuel inside the tank can cause displacement from the trajectory of movement, and can create undesirable loads on the structure, the result of which (in the worst case) will be its destruction.

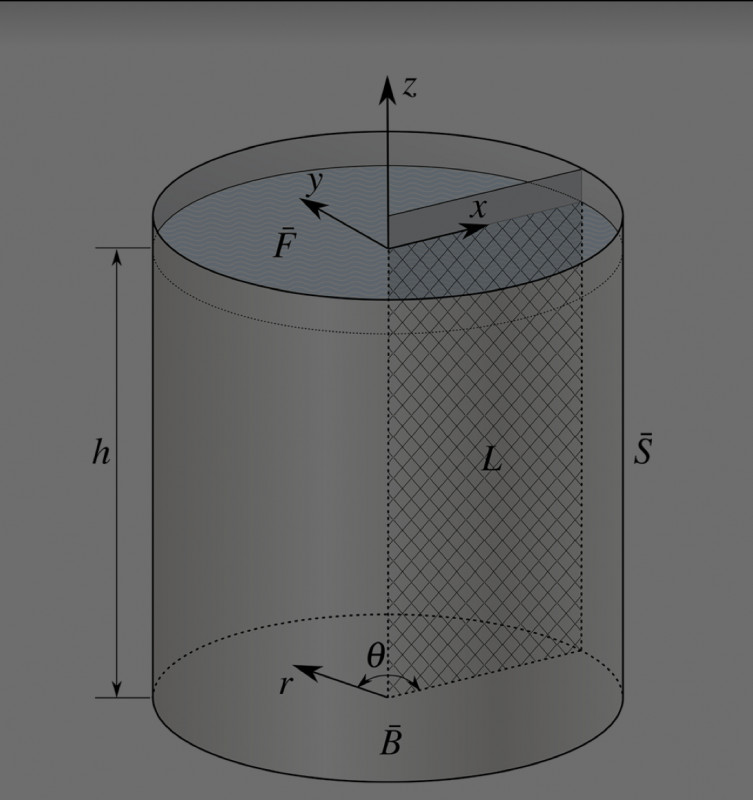

«With Oleg Motygin, my student, we investigated the free vibrations of the liquid in vertical cylindrical vessels and found that, in the presence of a vertical radial partition inside the tank, the frequencies of free vibrations decrease. Thus, the effect of breaking the axial symmetry manifests itself. It is important that the lowest frequency, which has the greatest impact on the formation of side effects, is significantly reduced,» said Nikolai Kuznetsov, the chief researcher of IPMash RAS.

In addition, the presence of a radial partition fixes the location of the maxima and minima of the elevation of the free surface, this makes the impact of waves on the tank more predictable and allows for providing proper reinforcement of the structure.